Study of on-site upgraded livestock biogas production and carbon emission reduction by substituting coals for thermal power generation

HTML: 0

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

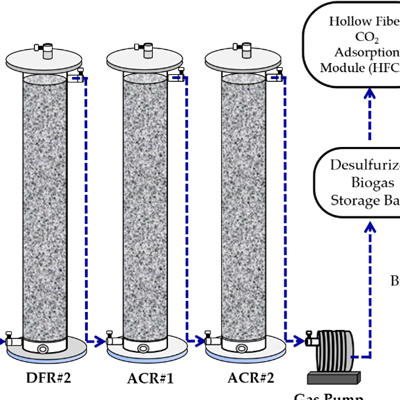

The objective of this project is to integrate a farm-scale bio-desulfurization facility with a novel biogas hollow fibre adsorption module for biogas desulfurization and bio-natural gas production. In this study, the desulfurization experimental results showed that the bio-desulfurization system can remove 96.7 ± 6% of H2S from the biogas after an approximately two-month enrichment period. The average CH4, N2, and CO2 concentrations in raw biogas were 63.4, 15.2, and 21.1%, respectively. As for biogas upgrading experiments, the inlet biogas flow rates were applied from 5 to 20 L/min. The removal efficiency of CO2 under all biogas flow rates was 100%. Meanwhile, methane was promoted from 60% to nearly 94% (i.e. 57% increase in methane concentration). The replacement of anthracite and coking coal by upgraded biogas might reduce 44.4% and 42.5% of CO2 equivalent, respectively. The achievement of this project pursues the mitigation of carbon dioxide emissions by using upgraded pig biogas which can be enlarged and extended to all decentralized pig farms worldwide.

How to Cite

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Copyright (c) 2023 The Author(s)

PAGEPress has chosen to apply the Creative Commons Attribution NonCommercial 4.0 International License (CC BY-NC 4.0) to all manuscripts to be published.

https://doi.org/10.4081/peasa.4

https://doi.org/10.4081/peasa.4